Усовершенствованный оксид алюминия (Al2O3): обеспечение высокотехнологичных применений с высокой точностью и надежностью.

Абстрактный

Оксид алюминия (Al2O3), Оксид алюминия, широко известный как высокочистый оксид алюминия, представляет собой универсальный и высокоэффективный керамический материал, широко используемый во многих передовых отраслях промышленности благодаря своей исключительной диэлектрической прочности, термической стабильности, химической инертности и механической твердости. В данной статье изложены ключевые свойства, области применения и технические характеристики высокочистого оксида алюминия, с акцентом на его важную роль в упаковке полупроводников и покрытиях литий-ионных батарей. Кроме того, в ней освещаются производственные и снабженческие возможности компании UrbanMines Tech., ведущего китайского производителя, приверженного качеству, индивидуальному подходу и надежным экспортным услугам.

1. Введение

Оксид алюминия — это не просто сырье для производства алюминия; это краеугольный камень современного высокотехнологичного производства. От микроэлектроники и хранения энергии до оптики, катализа и защитных покрытий, уникальное сочетание свойств оксида алюминия делает его незаменимым. С ростом спроса на миниатюризацию, энергоэффективность и высокую надежность в электронных и энергетических системах потребность в точно спроектированном высокочистом оксиде алюминия никогда не была столь велика.

2. Свойства и характеристики материалов

Высокочистый оксид алюминия классифицируется по фазовому составу, уровню чистоты, гранулометрическому составу и содержанию примесей, причем каждый параметр подбирается в соответствии с конкретными требованиями применения.

2.1 Контроль чистоты и наличия примесей

- Высокочистые марки: оксид алюминия 4N (99,99%), 5N (99,999%) и 6N (99,9999%) необходим для чувствительных применений, таких как инкапсуляция полупроводников и оптические компоненты.

- Низкий уровень альфа-излучения: критически важен для упаковки полупроводниковых компонентов, чтобы предотвратить программные ошибки в запоминающих устройствах. Технические требования часто предусматривают содержание урана (U) и тория (Th) ниже 3 ppb, с минимальным количеством примесей железа, натрия и хлора.

- Пример спецификации:

- Содержание Al₂O₃: ≥ 99,7%

- SiO₂: < 0,15%, Fe₂O₃: < 0,1%, Na₂O: < 0,1%

- Влага: < 0,1%, Потери при прокаливании: < 0,1%

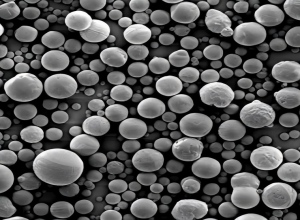

2.2 Размер и морфология частиц

Точная гранулометрия является определяющей характеристикой конкретного применения:

- Сферический оксид алюминия: размеры D50 варьируются от 1 мкм до 45 мкм (например, 2,8 мкм, 5,8 мкм для оптимизации плотности упаковки в полупроводниках).

- Несферический оксид алюминия: D50 от 1,5 до 10,5 мкм, используется в покрытиях и композитах, где удельная площадь поверхности и плотность в сыром состоянии имеют решающее значение.

- Площадь поверхности BET: Обычно < 1,5 м²/г для покрытий, чтобы обеспечить правильную рецептуру суспензии и адгезию.

2.3 Фаза и кристаллическая структура

Альфа-фаза оксида алюминия (α-Al2O3) является наиболее термодинамически стабильной формой, обладающей превосходной твердостью, теплопроводностью и электроизоляционными свойствами. Для обеспечения стабильного процесса спекания и получения однородной микроструктуры часто выбирают кристаллы размером 2–3 мкм.

3. Ключевые области применения в высокотехнологичных отраслях промышленности

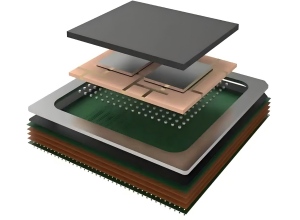

3.1 Упаковка полупроводников

Сферический оксид алюминия с низким альфа-параметром используется в качестве наполнителя в эпоксидных компаундах для формования (ЭМК) с целью повышения теплопроводности, снижения коэффициента теплового расширения (КТР) и обеспечения защиты от излучения. Распределение частиц по размерам (например, бимодальное 2,8 мкм и 5,8 мкм) оптимизировано для максимальной плотности упаковки и минимальной вязкости.

3.2 Покрытия сепараторов литий-ионных батарей

Высокочистый α-оксид алюминия (D50) < Материал (4 мкм) наносится в виде керамического покрытия на полимерные сепараторы. Он улучшает термическую стабильность, предотвращает образование дендритов и повышает смачиваемость электролитом, тем самым увеличивая безопасность батареи и срок ее службы. Материал смешивается со связующими веществами для образования стабильной суспензии, обеспечивающей равномерное покрытие.

3.3 Другие расширенные возможности применения

- Конденсаторы: выступают в качестве диэлектрического барьера благодаря своей широкой запрещенной зоне.

- Катализ и адсорбция: Высокопористый оксид алюминия в качестве носителя катализатора или осушителя.

- Конструкционная керамика: используется в износостойких покрытиях, биомедицинских имплантатах (например, эндопротезах тазобедренного сустава) и броневых системах.

- Полировка и абразивы: Сверхтонкий оксид алюминия (диамантин) для прецизионной полировки в оптике и часовом производстве.

- Высокотемпературная изоляция: например, в качестве огнеупорной футеровки печей.

4. UrbanMines Tech.: надежный партнер из Китая.

В условиях растущего мирового спроса на специализированный глинозем компания UrbanMines Tech. выделяется как надежный поставщик, обладающий глубокими техническими знаниями и клиентоориентированным подходом.

4.1 Производственное совершенство

— Наши специализированные производственные линии во внутренних районах Китая оснащены для производства высокочистого глинозема с низким содержанием альфа-кислот при строгом контроле качества.

— Мы предлагаем гибкие размеры партий — от опытных образцов до полномасштабного производства — обеспечивая короткие сроки выполнения заказов и поставки точно в срок.

4.2 Возможности индивидуальной настройки

— Мы подбираем чистоту, распределение частиц по размерам, морфологию (сферическая/несферическая) и профиль примесей в соответствии с точными требованиями заказчика.

— Предоставляется техническая поддержка для оказания помощи в выборе и интеграции материалов.

4.3 Доказанная надежность и опыт в сфере экспорта

— Благодаря 16-летнему опыту работы в отрасли, мы выстроили долгосрочные отношения; более 60% наших клиентов являются нашими партнерами более 5 лет.

— Мы обладаем всеми необходимыми экспортными лицензиями, в том числе на продукцию, связанную с редкоземельными элементами, что обеспечивает бесперебойную и соответствующую требованиям законодательства международную логистику.

4.4 Преимущества продукции «Сделано в Китае»

— Развитая промышленная экосистема Китая предоставляет конкурентные преимущества в области поставок сырья, передовых технологий переработки и масштабируемого производства.

Компания UrbanMines Tech. использует эти преимущества, придерживаясь при этом международных стандартов качества (ISO, RoHS, REACH).

Высокочистый оксид алюминия является важнейшим фактором инноваций в электронике, системах хранения энергии и современной керамике. Для удовлетворения жестких требований современных применений необходимы не только передовые материалы, но и надежная и гибкая цепочка поставок. Компания UrbanMines Tech. сочетает в себе высокоэффективные продукты с возможностью индивидуальной настройки и надежными экспортными услугами, что делает ее идеальным партнером для глобальных клиентов, ищущих качественные решения на основе оксида алюминия.

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ